Titanium Nitride (TiN) Coatings

As part of our advanced coatings and surface solutions offerings, Pulse offers titanium nitride (TiN) coating capability. These coatings are commonly used within cardiac rhythm management (CRM) devices but provide benefits in other neural interfacing applications too. The performance and functionality of CRM devices depend greatly on the energy required to pace a heart muscle. This is where a TiN coating can prove beneficial.

Cardiac Rhythm Management (CRM) Applications

The performance and functionality of cardiac rhythm management (CRM) devices depend upon the energy required to pace the heart muscle tissue, which is a function of programmed pulse width/amplitude, and the voltage delivered between the electrodes, i.e. the anode and the cathode. This is clinically relevant, in that optimizing the pulse width and amplitude can significantly affect current drain and battery longevity of the device. It is the electrodes that provide this pivotal function in CRM devices such as pacemakers. Electrodes are metallic conductors that mediate the transition from electron flow in the electrode to ion/ionic flow in the tissue via reactions at the electrode-tissue interface.

Material Choice

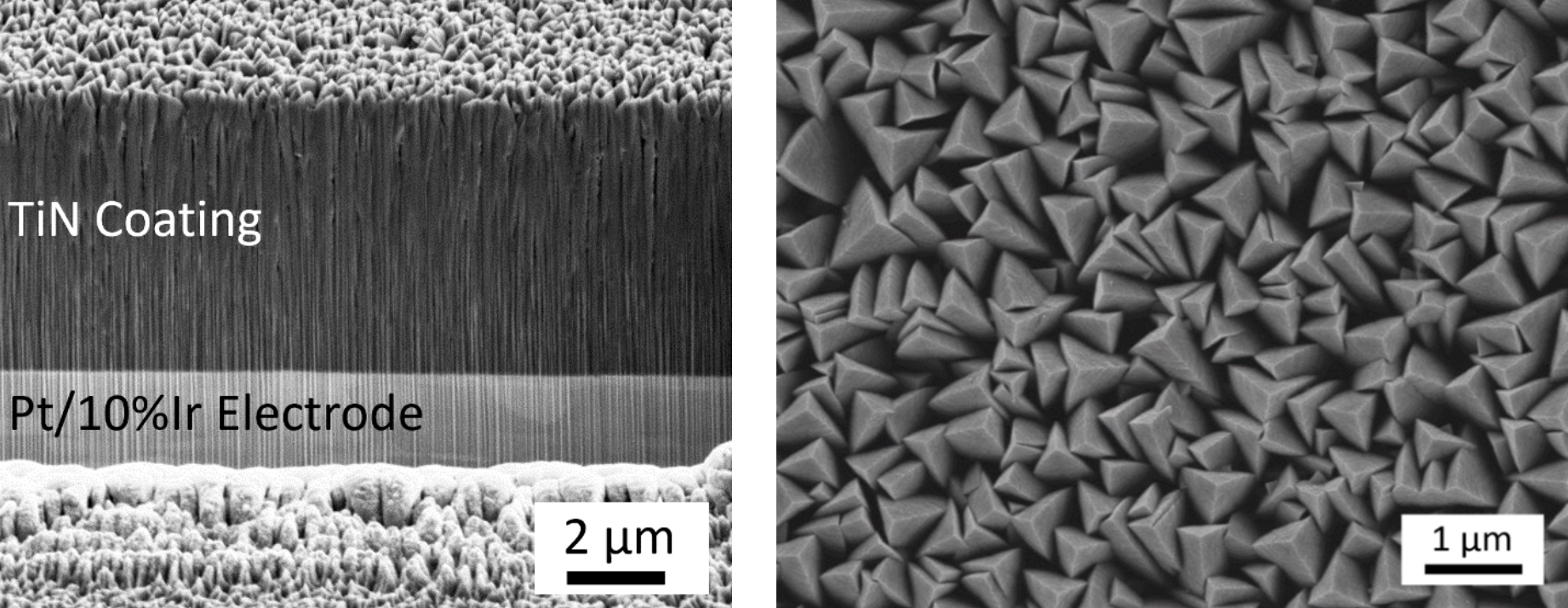

When choosing materials and surface technologies for the electrodes, material properties, surface structure/microstructure, electrochemical properties, and charge-transfer characteristics have to be considered. The surface must be able to transfer the electrical stimulation and also sense the cardiac response. Generally speaking, charge transfer in CRM devices should take place by double-layer charging/discharging thus the need for capacitive charge-injection, which is also desirable because no chemical species are created or consumed during a stimulation pulse. High charge-injection capacity is only possible with capacitor electrodes that are porous or employ high dielectric constant coatings.

Titanium nitride (TiN) coatings have traditionally been used as a surface coating technology on Platinum-Iridium (Pt/Ir) electrodes for CRM applications. TiN is a chemically stable metallic conductor with good biocompatibility, wherein charge is injected through the electrode-electrolyte double layer, and large charge-injection capacities are obtained by fabricating electrodes coated with high surface roughness/area TiN coatings. The surface structure of the TiN coating is important in that it affects the in-growth of the electrode to the cardiac tissue as well.

At Pulse Technologies, we have extensive experience with TiN coatings deposited via physical vapor deposition (PVD).

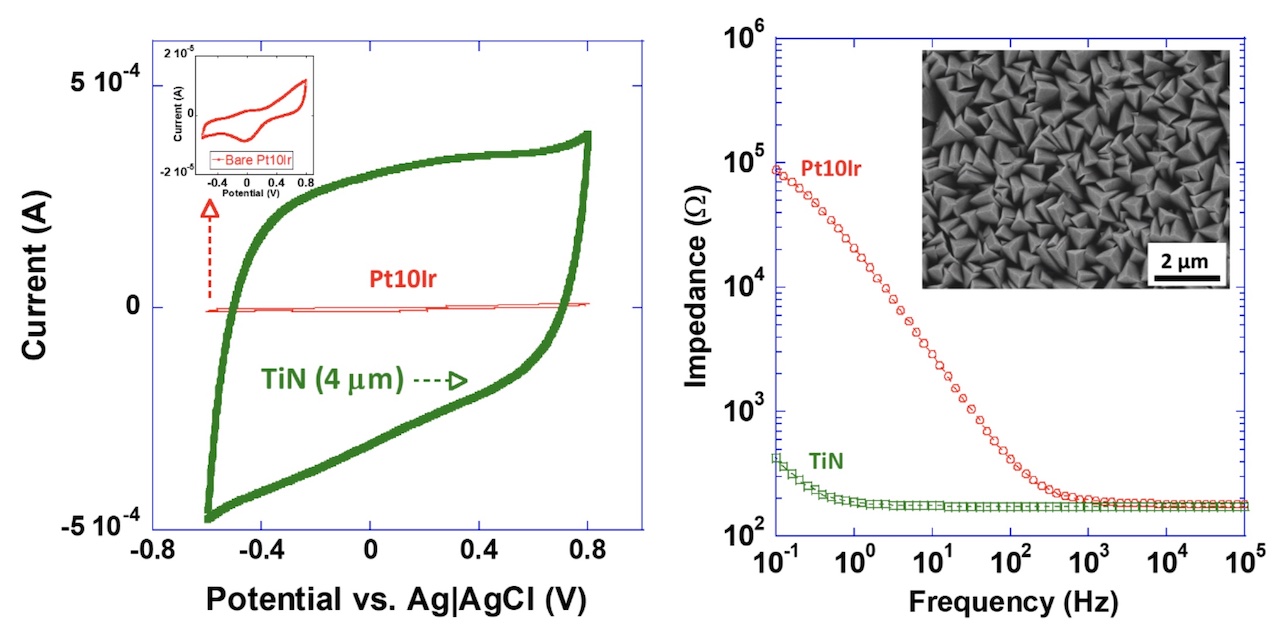

Performance Results

Our TiN coatings offer exceptional capacitance and charge injection capacity while substantially reducing impedance. In the diagrams below, note the benefits of TiN coatings related to charge storage capacity (left) and reduced impedance (right).

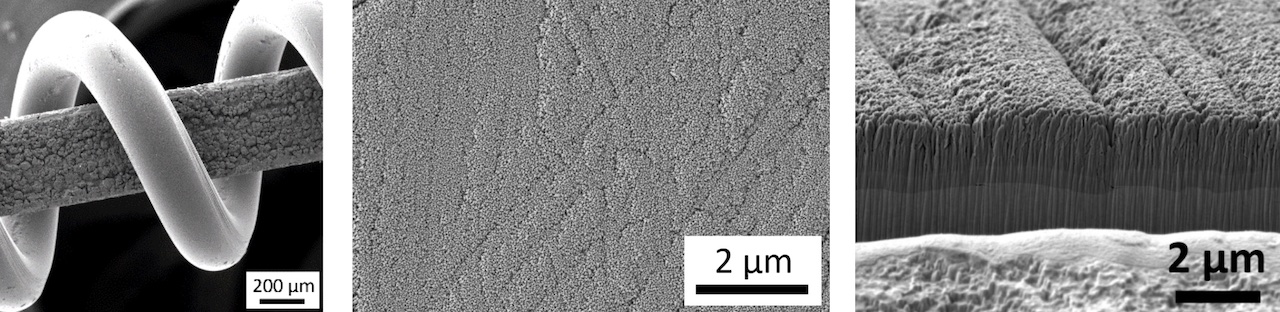

Inverted Cylindrical Magnetron (ISOFLUX) Technology For Complex Geometries

TiN coatings are often deposited on complex electrode geometries such as fixation leads. Synthesis of homogenous coatings over three-dimensional and complex surfaces while maintaining the desired microstructural and electrochemical properties of the coating can be challenging.

At Pulse, we offer a unique solution by employing inverted cylindrical magnetron (also known as Isoflux) cathodes, which sputter inward from the surface of cylindrical targets. These cathodes are ideal for coating cylindrical parts or helix structures that would otherwise be difficult if not impossible to coat uniformly.

Find out how our coatings can improve your device.

Contract Manufacturing

Advanced Technology

Capabilities

© 2021 Pulse Technologies, Inc. All rights reserved.

Careers

Careers Contact

Contact